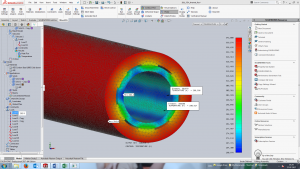

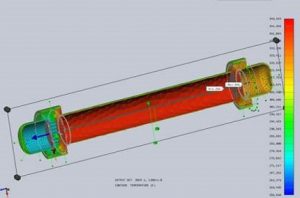

Double Wall Shell & Tube Heat Exchangers

Please contact us with your heat exchanger requirements. AF Pipes offer a wide range of designs and possibilities for double wall shell & tube heat exchangers, and the final design depends on a combination of the process requirements and the design limitations. Therefore it is recommended to contact AF Pipe Solutions at an early stage in the process to assess the suitabilty of the design. AF pipe solutions wil be happy to provide guidance at the planning stage. The shell and tube heat exchanger is available in a variety of configurations for double wall safety, as described below.