We are very pleased to offer this novel compact inner pipe support to the market for double wall pipe arrangements and double pipe support.

The comparison below shows the potential material and weld savings for this support type:

| 4” inner pipe support | 3” Inner pipe support | Reduction | |

| Outer pipe kilo pr meter |

16.32 kg

|

6.56 kg | 60% |

| Weld cross section

|

2040 mm^2

|

809 mm^2

|

60 %

|

| Dry air consumption /

2 x50 m double wall pipe * |

40 % |

Issues with double wall pipe design

The most sensitive part of a double wall pipe system is how to support the inner pipe. If the pipe is not correctly supported there will be problems excessive movements of the inner pipe, leading to premature failure of pipe supports. Particularly if compensation for these movements isn’t considered correctly. The common inner pipe support system is very complicated to install and requires large amounts of skilled labor. It is particularly around bends that problems initiate, the inner pipe support has to be accurately located and installed at the correct radial angle, so it moves in the correct direction relative to the thermal displacement that occurs during both installation and in service. If not installed correctly, premature failure may be expected through excessive stress, or cyclic stresses. This can also lead to metal to metal contact on the outer pipe, which is also undesirable.

Furthermore due to weld shrinkage during production, additional stresses can be introduced onto the inner double pipe support, again leading to premature failure. This is particularly evident when supports are welded in place, as is typically done these days on most double wall pipe installations.

The new inner pipe support concept improves many parameters and descreases the installation complexity. It is very simple to install and has a higher safety factor due to compensation for misalignment of piping sections during installation which is extremely common. It will also obtain higher level of displacement between the inner and outer pipe.

Depending on the exact piping dimensions, and therefore inner pipe support size, it may be preferntial to consider the new inner pipe support as an axial support , with limited radial freedom. This of course depends on the exact specification of the double pipe support chosen, but from our point of view can be considered the most robust method of designing the double wall pipe installation. Therefore we recommend that the inner pipe support is installed together with our Flex Bend concept. The Flex Bend is the ultimate pre-fabricated product for the most robust double wall pipe solution, that eliminates all the problems that have been described previously.

Advantages of the complete solution:

- Very simple to install.

- Can obtain minimum +/- 10 mm displacement around bends ( for the most compact size).

- Improved slide pads,and securing of slide pads

- Compact design for cost down on material, welds, duct fans, and use of dry air.

- Reduced installation spaces, and reduced spaces required for piping routings.

Technical information

Design Phase

Calculations are performed to thoroughly investigate the structural behaviour of the double pipe arrangement with the new double pipe support installed.

The double pipe flexible support is designed to accommodate movement in the inner pipe of a double wall pipe in the axial and radial directions. Movement in the axial direction is unlimited due to the sliding action of the bearings, and movement in the radial direction is limited to the specified allowable elastic deformation of the supports themselves.

The principle design criteria for the supports are the dimensions of the inner pipe and outer pipe. The design is also made to ensure there is a good fit of the supports that are clamped around the inner pipe, and the slide bearings have permanent contact with the outer pipe inner surface in all scenarios. Designs are checked against pipe standard tolerances, and manufacturing tolerances to ensure a good fit, and no metal-to-metal contact. The design is initially constructed based on a few standard design criteria, then design simulations are performed to optimize the stress distribution and deflection characteristics of the spring form itself. This is the first stage in the simulation process. Once a good spring form design has been produced, then the entire flex support assembly is simulated in three stages:

- The initial clamping of the assembly (this stage also determines fastener torques),

- The assembly stage, once the assembled flex support is compressed

- The behavior of the final assembly in the piping arrangement. The last stage of the process is particularly important as it determines the calculated maximum deflections, and stiffness properties of the flex support assembly.

Finally, modal characteristics of the assembled support are analysed against a range of frequency inputs, to establish any issues that may be observed due to resonance. This leads to the recommended spacing between the supports, in order to avoid any resonance issues. The calculations cover the following list of topics:

Structural analysis

(*) stress analysis for the system “in place”, i.e. springs compressed and full contacts established among the bearings and the external pipe

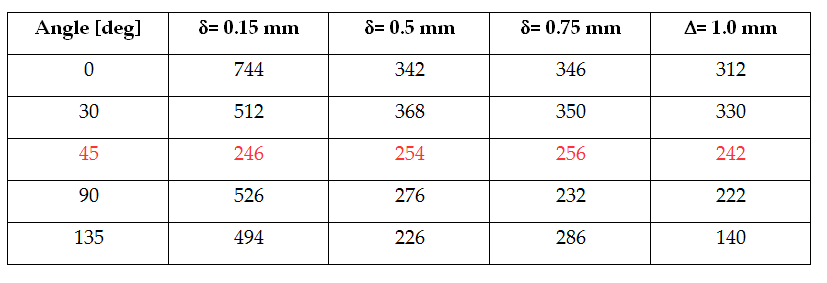

(**) stress analysis for an increasing radial displacement of the inner pipe, along different radial directions: polar diagrams of the overall stiffness of the system

modal analysis

(***) modal analysis

(****) maximum deflection calculation

These analyses have been performed in elastic-plastic regime, by the use of material modelling of Annex 3D of ASME VIII Div. 2.

Typically, the more compact design result in higher stiffness than the larger 4″ types. Here is the features for the stiffness listed as an example:

Design Validation and Testing

- Design validation testing

The first series of tests are to confirm stiffness & maximum deflection properties of the flex support assembly, and allow for release of final specifications for the specific support. During the design phase design simulations are performed to establish the maximum and minimum stiffness properties of the double pipe support. These characteristics form the basis for the installation recommendations regarding exact angular placement of the supports. This is specified in the installation specification as below:

Radial Stiffness & Deflections

| Minimum | Maximum | |

| Angular Position from vertical (pad centre, °) | x | x |

| Stiffness (kN/mm) | x | x |

| Max Deflection at minimum & maximum stiffness | ||

| Max deflection (mm) | x | x |

| Durability (guaranteed cycles at max deflection) | x | x |

In order to verify the design simulations the double pipe support is installed in a test rig, and tested for stiffness and deflection properties. For stiffness testing a load cell is inserted in between the pneumatic cylinder and the test piece in order to directly measure the force exerted by the cylinder. The deflection is then set by adjusting the limit switches. This methodology allows for precise specification of stiffness properties.

For durability testing a robust connection piece is used to run thousands of cycles at the specified maximum deflection until failure occurs. The principle for success of the test is based on the expected number of cycles during the lifetime of the piping system. The estimated number of cycles is based on twenty start-stops per week, over a fifty year period, equating to 104,000cycles. Minimum lifetime is typically specified to 150,000cycles to include a degree of safety in the system. In case of premature failure during testing, then then maximum deflection specification can be reduced.

2. Flow testing

Before flow testing occurs, in the design phase, CFD simulation of the flow behavior is performed to make an estimate of the pressure loss across 1 double pipe support. Flow testing is performed in a length of piping, and plurality of supports, in order to provide representative data for a real-life situation. Pressure drop is measured using a manometer tube installed in the piping. A ventilator fan with known specification is applied, and the bulk flow velocity is measured through the piping with three different volumetric flow rates.

Results are recorded in the following table:

| Ventilation flow (m3/hr) | 15 | 30 | 60 |

| Pressure drop (Pa) | x | x | x |

Validation of CFD simulation is then performed for information purposes.

These additional tests are performed, but not necessarily specified on the product specification, or performed on batch level:

- Corrosion test: consists of addition of saturated salt water solution sprayed onto the flex support during durability testing. Also, long term salt water bath dip, to test applicability of materials.

- Wear test: consists of erosion allowance measurement of the bearings by measuring mass of axial bearing support pad before and after a specified number of cycles.

- Joint test: measurement of force required to remove pad from spring form.