Please go through some of our components, their functions and design criteria

Double Wall Pipes and Production Process

Our core expertise is double wall piping. Double wall pipe production is a complex component, where the location, and dimensions of each part is critical to a succesful installation. We have developed a unique double wall pipe production and installation process, which prevents failures in the piping after installation, and ensures years of problem-free operation.

First Stage in the Double Wall Pipe Production Process

Once the piping line is confirmed at the first kick off meeting, then we will order all the materials required. As material delivery is typically the longest lead time in the process, then it is important to get the double wall pipe production underway as soon as possible.

Once the first materials are received then double wall pipe production can start on the inner & outer piping. The additional piping components and fittings will also be ordered at this stage, an overview is given below:

Components of the double wall pipe

Pipe materiale for 330 bar, up to 420 bar design pressure.

Inner pipe

Duplex or Super Duplex, versus austenitic steel 316

Duplex is selected from these three parameters for the inner pipe for methane engines:

1. Strength – duplex is lighter, stronger and more flexible than 316L

2. Corrosion – duplex is a much more durable material. This is a big advantage as the inner pipe is hidden inside the outer pipe, and very difficult to inspect, and even more difficult to replace.

3. Thermal expansions – duplex has a lower thermal expansion value than austenitic steel 316. The inner pipe has the largest temperature fluctuations in the construction. If 316 is applied as the inner pipe, more expansion bends and loops will be required to compensate for the thermal stresses.

Outer Pipe

For the outer pipe S316L is recommended because the austenitic steel types can go lower in temperature than Duplex without being brittle.

The low temperature may occur if the 300 bar compressed gas is cooled down from cold ambient temperature and a leak occurs.

With a 24/7 dehumidified ventilation air supply according to our specifications, 316 L can be the selected material for the outer pipe.

For the outer pipe it is important to focus on the temperature environment where the pipe is located If the pipe is on deck it should be sheltered from the sun due to avoid uncontrolled heat expansion, and thereby uncontrolled stress levels of the inner pipe. This is naturally a design criteria we consider during our pipe design.

The sections of the double wall pipe arrangement are produced in our 100% stainless steel production environment. It is very important to work in a stainless steel environment, to avoid contamination with particles from carbon steel. Our quality control keeps track of this throughout the proudciton process from tool handling to installation.

We apply a pre-flushing technique, pipe section sealing, and very meticulous installation procedure to guarantee a clean pipe to our specified standard.

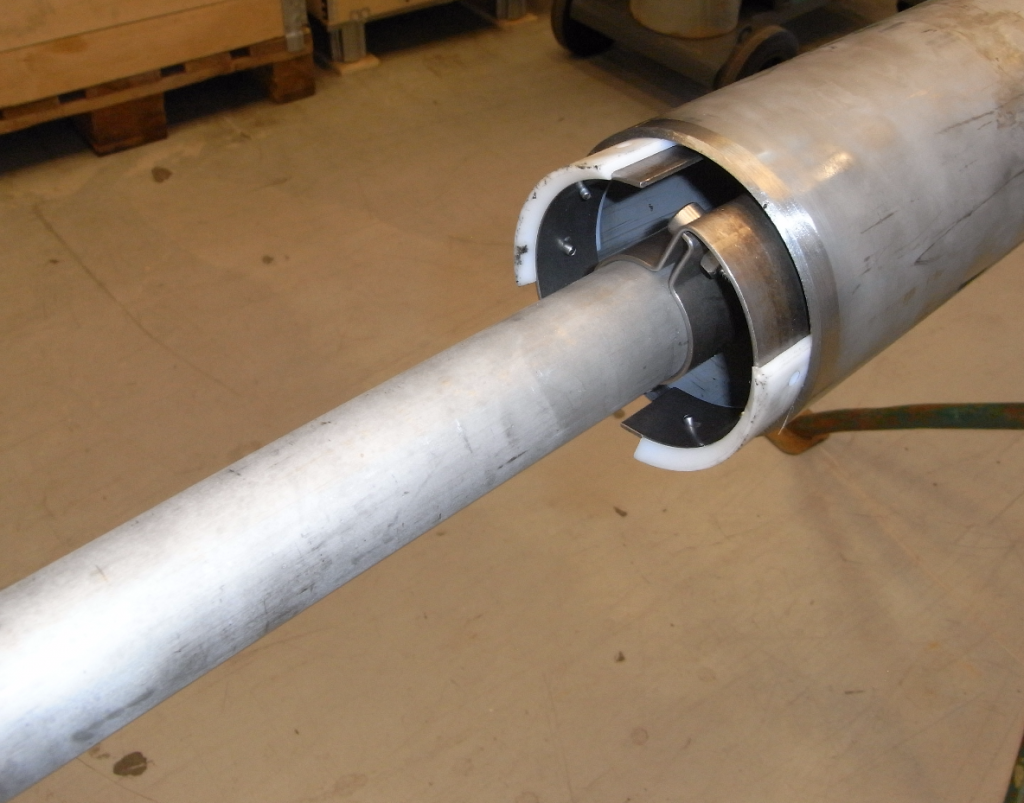

The core element of the double wall pipe construction is the inner pipe support.

By use of spring energised high level polymer pads, the inner pipe support will never lose contact with the outer pipe wall.

The material of the bracket part is a stainless steel spring material.

This material of the bracket part does not have as high corrosion restance as the pipe material, and requires a 24/7 dry air environment.

The pads

With the correct fine surface requirement on the inside wall of the outer pipe, the Peek HPV pads will easily last the service time af the vessel.

The limits

The location of the inner pipe support is highly important.

If the inner pipe support is placed at the wrong angle, a rigid and inflexible contact between the inner and outer pipe can occur. This can be fatal and the inner pipe support bracket can break.

The inner pipe can be displaced a maximum of 6mm in radial direction. If the radial displacement is more than 6mm, the stress level of the bracket can be over-exceeded, and the bracket can come in contact with the outer pipe, thereby increasing the risk of steel to steel contact.

Therefore it is extremely important that the location of the inner pipe support is performed by skilled and trained personnel, and documentation are of the process is available.

To control and guide the expansions between the inner and outer pipe, we need anchor points. For this, we have designed a strong inner pipe anchor that binds the inner and outer pipe together

Our solid outer pipe anchor that fix the outer pipe in all 3 directions

We install inspection plugs on the outer pipe to get access to the inner pipe.

The inspection plugs are made in high strength brass.

The use of brass for the plug screw is in compliance with class requirements, and is to avoid the risk of sparks. If a steel plug was used, steel to steel contact will be present.